Root Cause Analysis (RCA) and Asking the 5 'Whys'

What's causing the recent influx of service tickets at your organization? Why are customers complaining about long wait times for a reply? Why are your customer service staff resigning regularly? Sometimes, persistent issues can be related to a product or service you offer. If you find yourself asking questions like this or fielding inquiries about faulty products with regularity, it might be time to conduct a root cause analysis. We'll dive deeper into what this process entails below, but it is important to determine problems beyond what they appear to be on the surface.

Identifying an issue is one part of the equation, but determining the build-up can lead to a more concrete solution and avoidance in the future.

What is 5 Whys Root Cause Analysis

Root cause analysis, shortened to RCA, is an approach taken to analyze an issue before trying to fix it. It is the process of going beyond the issue, and finding out what caused that issue to begin with. A short term fix can be more costly to an organization in the long-run, so an RCA aims to permanently fix the cause. Root cause analysis is a reactionary method. The problem occurs before this method is deployed.

There are many ways to go about a root cause analysis, however we will focus on the 5 Whys analysis in this piece.

Identify Root Causes Using the 5 Whys Analysis

If you are looking for a root cause analysis process for beginners, look no further than the 5 Whys analysis. It is a simple set of five questions that you can assign answers and actions to, in order to solve issues in the workplace.

Are you wondering how to do a root cause analysis? Start by answering these questions:

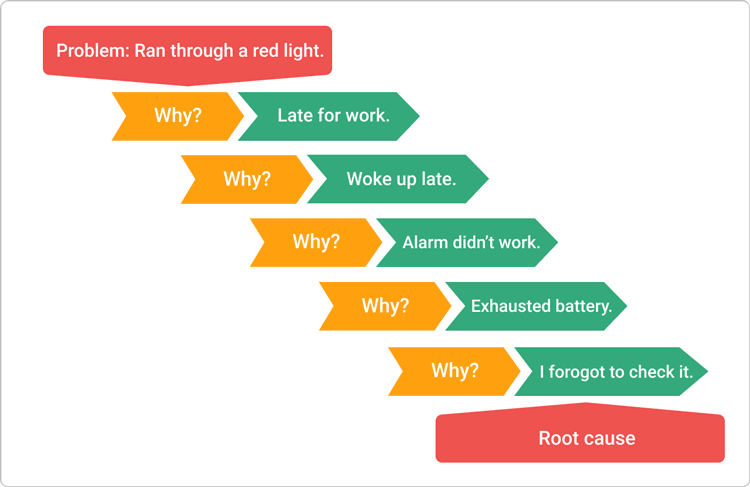

What is the problem: Document what the main, overarching issue is in the workplace. For example, you could cite that there are issues with slow customer service response times.

Why is the issue occurring: Look a little deeper into the problem, and try to attempt to identify a cause. To use our example of long customer service reply times, you may identify a cause as understaffing or an inefficient workflow.

Stumped? Ask deeper questions: After step 1 and 2, if you still can't identify a root cause, you may want to ask yourself why coming to this conclusion is so difficult. In this case, you may need to bring in others for consultation and opinions.

Continue asking questions: Until you find an answer, continue to ask questions. Essentially, step 4 involves repeating step 3 until you can come to a conclusion.

Continue asking questions: Use step 5 as an additional spot to ask questions if you have yet to reach a conclusion.

Conclusion: Identify the root cause.

The process may be called the 5 Whys, but it can be completed in fewer steps. Steps 4 and 5 (if applicable), simply involve expanding on step 3, asking deeper questions or consulting with other individuals, until a consensus on an issue is reached.

Benefits of the 5 Whys

It is completely normal to get complacent when things go wrong in the workplace. You panic and send employees in several different directions in search of a solution. This only compounds an already difficult situation. The 5 Whys is a great system to help keep the peace in chaotic times. It gives you as the CEO or project leader a "checklist" of questions to answer before hitting the panic button.

There are three main benefits of the 5 Whys:

- Identifying the root cause of the problem. This is the main goal.

- Breaking things down. Identify and explore the different issues associated with an overall problem. Make connections and identify how each issue relates to one another.

- The 5 Whys tools include nothing more than you and your own team's knowledge. It is a set of questions to guide you to an answer, simple as that.

5 Whys Examples

The 5 Whys template can be made up however you would like it to be, as long as it allows you to arrive at your root cause. Now that you understand the components of the template, let's look at a couple of examples.

Example 1: Why did you run a red light this morning?

Example 2: Why have we missed 4 of 5 product launch deadlines this year?

This 5 Whys template will follow a similar pattern as the one outlined above. This example will provide a more detailed, action-oriented process.

- What is the problem: The Super Smartphone company has missed 4 of the last 5 product launch deadlines they set by well over 2 months in each instance.

- Why is the issue occurring: It seems like there are problems with collaboration. The issue seems to be occurring because they are not receiving promised and necessary content from other departments in the organization in time for launch.

- Stumped? Ask deeper questions: Which departments are creating the bottleneck? It is discovered that the Development team is taking too long to provide item specification sheets, and they simply cannot launch without that.

- Continue asking questions: After speaking with the Development team, they indicate that they have had a product specification sheet draft ready weeks before the official launch. The issue rests with a lengthy review process implemented by senior leadership.

- Continue asking questions: The project lead on the Super Duper Smartphone product confronts the senior leadership team to find out what is causing the delay in the specification sheet review process. This should unveil the root cause of the issue.

Conclusion: After discussions with the senior leadership team, it is clear that they are having issues dividing up the work that comes into them for review. Since they are a group of three, they have decided to divide work for review based on the department it arrives from. This is a transition away from the "first available individual" process they were utilizing before.

The Bottom Line: Use 5 'Why' Analysis!

Identifying a problem in the workplace is easy. For example, your customer service response times are slow, or there are consistent delays in product launches. Root cause problem solving can be a bit more challenging, and it can often involve asking several questions until you come to a conclusion. The 5 Whys technique is a simple concept, but an important one. Identifying the root cause is often the first step in developing an action plan towards a more permanent resolution.

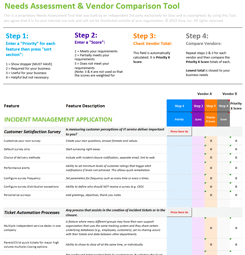

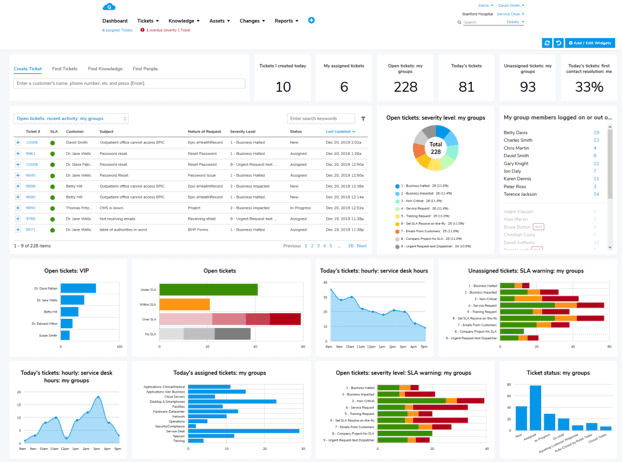

Download Our Free "5 Why's Root Cause Analysis Excel Template and Dashboard"

Are you struggling to get to the bottom of persistent issues in your business processes?

Our free 5 Why's Root Cause Analysis Excel Template and Dashboard is here to help. Based on the 5 Why's method of root cause analysis, this template is designed to simplify the process of identifying and addressing the root causes of problems, to help implement effective solutions and improve your operations.